4 Things to Consider When Buying Swivel Castor Wheels

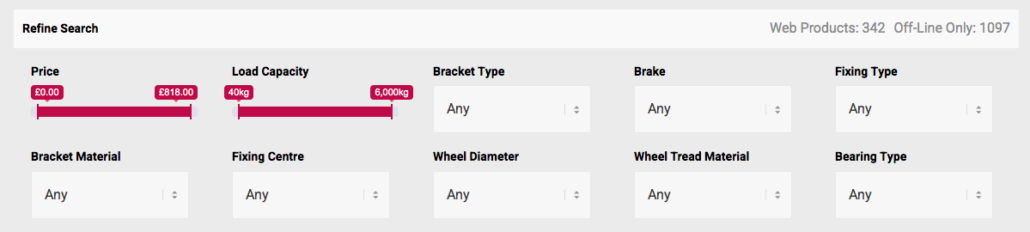

Swivel Castors add 360 degree mobility to equipment, helping you transport goods, tools and materials more easily. We stock over 1500 types of swivel castors, with various bracket materials, fixings, wheel diameters and bearing types. The huge choice that Keystone offers means we are used to advising our customers on the right castors for their application.

Understanding Your Requirements

Identifying the specific needs of your project will support finding the best swivel castors to use. The most important features to decide are load capacity, materials and braking requirements, so consider these first. Secondary factors include how the castors will be fixed, the wheel size and bearing types. These will depend on the materials the rest of the project is built from and environmental factors such as flooring type and the operating temperature.

Once you know some of these factors, you can use our search refinement system to find the perfect castors for your project.

1. Load Capacity: How Much Weight Should It Hold?

The main consideration when choosing castors is the maximum weight you intend it to hold. Our swivel castors range from 15kg to 6000kg, so there is plenty of choice.

Castor Configuration

The castor’s specification will show the load capacity of a single castor, rather than a set of castors. In most situations, you will be using more than one swivel castor to support your appliance, so consider how many and in what position.

- Four castors: each castor must be able to carry ⅓ of the gross weight.

- Three castors: each castor will need to support at least 40% of the gross weight. However, this configuration is suitable for smaller loads.

Calculating Gross Weight:

- Consider the weight of the equipment the castor will support. Whether it’s a chair, roll cage, dolly or hospital bed, it must be able to support itself.

- Add the maximum load the equipment will need to hold. If it will be used to move palletised goods, materials or machinery, this may be around 500-6000kg.

If you are manufacturing furniture, be aware that an adult may weigh more than 350kg. Particularly if you’re making hospitality furnishings, a client could face some tricky customers if the furniture won’t support them comfortably.

The load capacity is first here because it affects so many other options. A castor required to support 2000kg will rule out certain bearing types and materials.

2. What Type of Flooring Will It Run On?

The intended surface is largely a question of friction. If you are manufacturing wheeled products for general use, consider the types of flooring it might run on. Is it:

- Indoor or Outdoor?

- Carpet, concrete or lino?

The surface on which the castors will run affects the choice of wheel diameter, wheel tread material and bearing types.

High-Friction Flooring

On high-friction surfaces such as gravel, castors are much less likely to require brakes. However, they will need greater wheel sizes to roll easily when pushed.

We do not recommend swivel wheels for gravel as the friction can make it difficult to steer.

The wheel tread material will also need to be highly durable. If you also need a high load capacity, choose steel or cast iron. If loads are lightweight, a durable plastic wheel such as cast nylon will create less resistance, and less noise, than a rubber wheel.

In some indoor uses, such as castors for furniture, carpeted areas provide high friction. Large wheels may be inappropriate for furniture such as desks or chairs, so consider dual-wheel polypropylene furniture castors.

Low Friction Flooring

Flat concrete or indoor flooring such as lino, laminate or vinyl provides a great environment for smaller castors to run smoothly. However, some roll resistance is important for safety considerations. Avoid sliding or unsafe speeds with rubber wheel tyres.

Noise Levels

The wheel material chosen will also impact the noise of wheels as you move them along the floor. Rubber wheels are the best option for noise reduction, and will also protect the floor.

3. Choosing Bracket or Yoke Materials

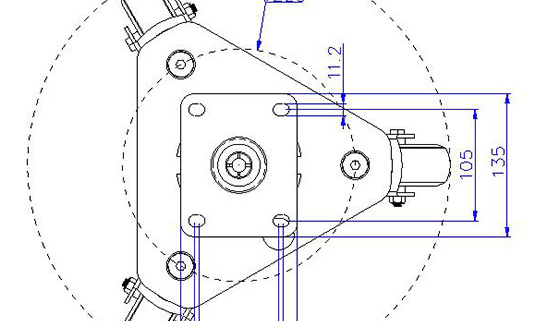

The bracket, yoke or castor frame is the part which houses the wheel. In swivel castors, the bracket is the part which enables rotation and requires regular lubrication to maintain.

We supply a range of castors with steel and aluminium brackets, with stainless steel, pressed steel, die-cast aluminium and more. The load capacity of your castors will impact the bracket material, as the maximum load capacity of an aluminium bracket is 1500kg.

4. Do You Need Brakes?

Brakes add stability and contribute to safety, stopping the equipment from rolling unnecessarily. We have a few braked swivel castors on our online store, with a much wider variety available offline.

Explore Our Castor Range

To find the right fit for your project, browse our swivel castors. There are huge benefits to the added mobility offered by a swivel wheel, and we hope our online and offline ranges provide a suitable fit. For any further advice or enquiries, do not hesitate to contact the Keystone Castors team. We’ll be happy to help.