Description

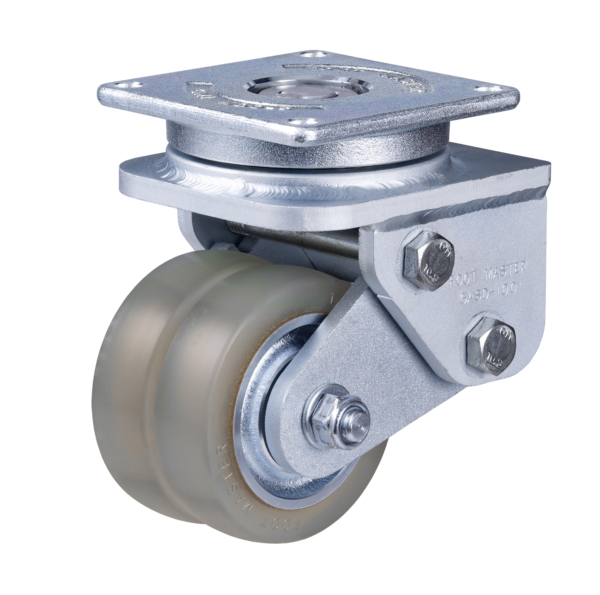

This Twin wheel Automated Guided Vehicle (AGV) Castor with 125m diameter wheels has a shock absorbing function and a bracket made from strong Forged steel that is zinc plated. There is double thrust bearing in the swivel head to achieve a high load capacity and maintain castor performance and durability.

The role of the spring in an AGV castor is different to that of a standard shock absorbing castor. In a standard shock absorbing castor, the spring absorbs shock and noise whereas, it’s role in a AGV castor is primarily to keep the wheels in contact with the floor.

When determining the overall height requirement of a shock absorbing AVG, it should be designed based on the spring cushion being fully compressed.

The shock absorbing pad made from a special rubber compound absorbs minor shocks and vibrations to protect the AGV unit. There is a 10mm range of compression which helps prevent the castors from losing contact with the floor which may be caused by small floor imperfections. An AGV’s castor leaving the floor when changing directions is often the cause of the AGV becoming unbalanced and coming to a stop by straying off its designated path.

The Top Plate is 145mm x 145mm and has 4 bolt holes that are spaced 120mm x 120mm, each with a 11mm hole diameter

This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, Having a twin wheel castor is great for reducing the effort required to swivel the castor and most efficient by reducing the amount of room the castor needs to turn the AGV Cart.

The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor.